The same table includes a value for mild steel on mild steel. Plain Carbon and Low Alloy Steels.

Beautiful Table Made In Stainless Steel Base In Polished Ebony Top In Vetrite Stainless Steel Dining Table Steel Table Base Steel Dining Table

In TPRC I pp 118690 curves 81 91 and 92 Tool Steel 141 C 023 Mn 0158 Si L Water Quenched 305 310 318 Tempered at 150C and air cooled 322 322 328 Tempered at 200C and air cooled.

Steel table values. Normalizing takes place when as-rolled material is heated back up to approximately 900C and held at that temperature for a specific time before being allowed to cool naturally. Static Coefficient of Friction. Always specify table data for 90 bends.

Track of which comparison criteria were used for a given steel each table within a chapter was sequentially numbered and appended with either the letter A or B. Steel cools as it is rolled with a typical rolling finish temperature of around 750C. 01 C 034 Mn 674 661 649 CS 91.

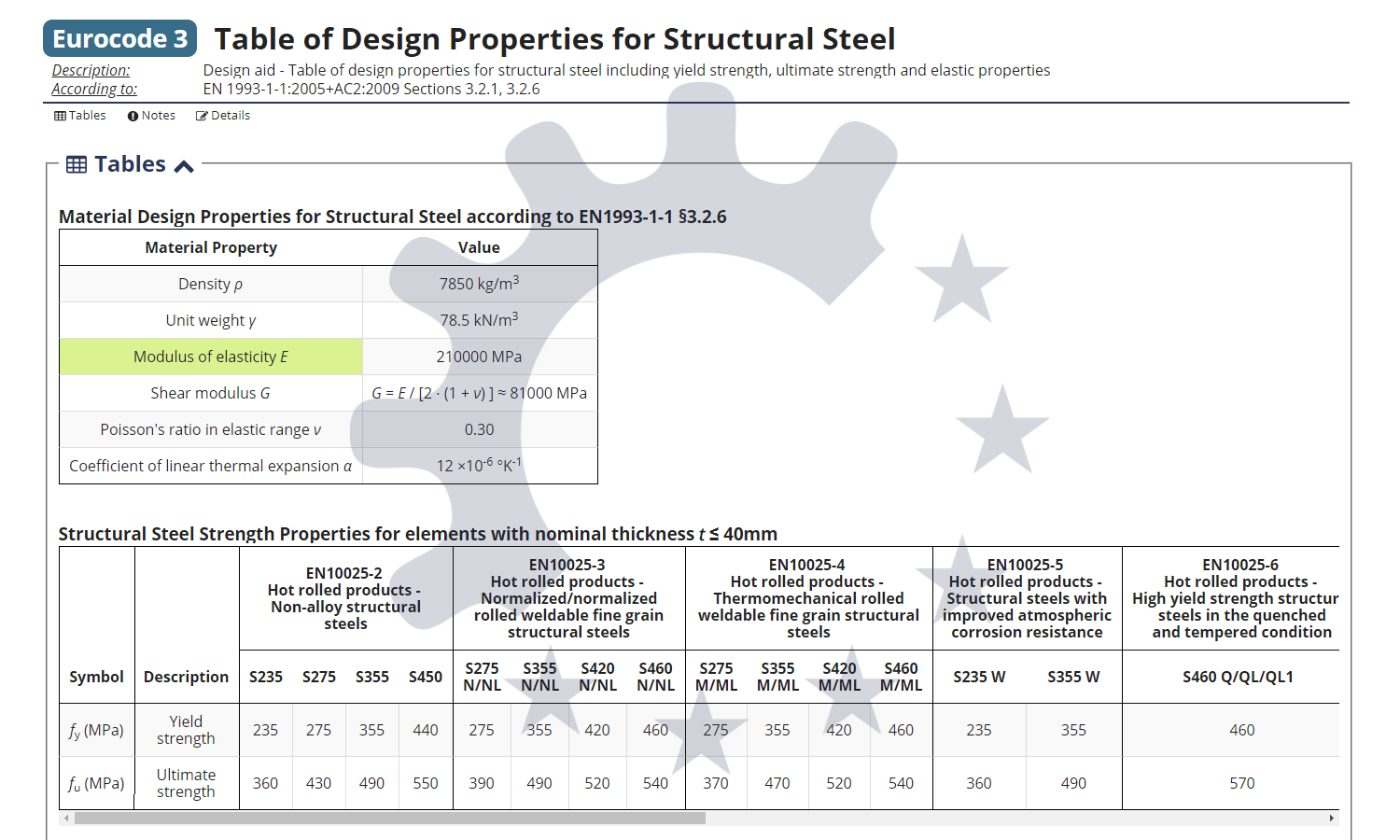

All SAE 1100 series steels are rated on the basis for 010 max silicon or coarse grain melting practice. Later we decided to open the tables for our visitors. For structural design it is standard practice to consider the unit weight of structural steel equal to 785 kNm 3 and the.

Concise Metals Data Handbook by JR. Adjustments to U-values in Table 6A2 for frames with thermal breaks. 044 C 067 Mn 540 527 519 List.

This pressure is used because most literature data are still given for this value 1 atm rather than for the current standard of 100 kPa 1 bar. 97 rows Reference Table. Plain Carbon and Low Alloy Steels.

124 rows Density Table of Metals and Alloys. Condition Annealed Cold Drawn. 17 rows Free Metal Price Tables and Charts Updated Daily.

Whereas table numbers ending with the letter B were mirrored from the A table. Spacers Separators Packaging M. Maximum Recommended Tightening Torques.

The mechanical properties shown are expected minimums for the sizes ranging from 34 to 1-14. 026 C 061 Mn 561 552 544 CS 92. Thereafter a second edition of the DCTHS was released in 1999 entitled Design Capacity Tables for Structural Steel Volume 2.

You can find in our tables both dimensions and properties for majority of the standard steel section like steel beams and columns channels angles steel hollow sections. Tables for Structural Steel Hollow Sections DCTHS which only considered tubular members. At first this part of the site was intended for internal use only.

The U-values in this table are based on the frame comprising 20 of the total window area. Plain Carbon and Low Alloy Steels. An effective concentration of 1 molL for each aqueous species or a species in a mercury amalgam an alloy of mercury with another metal.

Banding Placement Method Size Number M. Torque Tightening Values for Structural Steel Bolts. While somewhat of a challenge the aim of the DCT-v2HS and preceding DCTHSDCT was to.

Steel hardness conversion chart - all values approximate. AISI Steel Code Tables Shipping Packaging Table of Contents. If you only want to apply the bend table formulae include data that is not used in your design Radius 1000 Thickness 1000.

For windows with metal frames incorporating a thermal break or rooflights the adjustments given in Table 6A3 should be made to the U-values given in Table 6A2. Latest metal prices and charts by date and currency. Plain Carbon and Low Alloy Steels.

Davis table 141 includes values 031 static -023 sliding - for steel 1032. Table numbers ending in the letter A designate that the table was the main criterion used for comparison. Intermediate British Steels 1933 CS 81.

The table below lists out the density. For bends other than 90 the values are multiplied by 90 where is the specific bend angle in degrees. Below is a list of the recommended tightening torques for 129 109 88 zinc plated finish bolts.

The unit weight of structural steel is specified in the design standard EN 1991-1-1 Table A4 between 770 kNm 3 and 785 kNm 3. Platform Skids Pallets M. Steel that is then allowed to cool naturally is termed as-rolled material.

Any value not found in the table data is interpolated. DESIGN COEFFICIENT TABLES Hazen-Williams Friction Factor C Pipe Material Values for C Range HighLow Average Value Typical Design Value Plastic PVC Polyethylene pipe or tubing 160150 150-155 150 Cement or mastic lined iron or steel pipe 160130 148 140 Copper brass lead tin or glass pipe or tubing 150120 140 130. A partial pressure of 101325 kPa absolute 1 atm 101325 bar for each gaseous reagent.

Product Protection Methods M.

.jpg)

Aisi 4130 Alloy Steel Uns G41300

Steel I Section Dimensions And Material Properties Download Table

Modernist Stainless Steel Table Base Steel Table Base Stainless Steel Table Steel Table

Gallery Of Slender Strength The Mighty Grace Of The Stainless Steel Airtable 4 Stainless Steel Furniture Steel Table Legs Steel Table

Stainless Steel Fasteners Technical Data

Values Of Friction Angle For Sand And Between Sand And Steel Download Table

.jpg)

Structural Steel S235 S275 S355 Chemical Composition Mechanical Properties And Common Applications

Values Of Friction Angle For Sand And Between Sand And Steel Download Table

Stainless Steel Fasteners Technical Data

Nominal Values Of The Yield Strength F Y And The Ultimate Tensile Download Table

Chemical Composition Of Aisi 304 Stainless Steel Download Table

Stainless Steel Fasteners Technical Data

Grade Guide A36 Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

1 Relative Permeability Values Of Some Selected Materials 16 Download Table

Table Of Material Properties For Structural Steel S235 S275 S355 S420

Pressure Vessels Maximum Allowable Stress Values Oil And Gas Separator

Rectangular Steel Table Base Steel Table Base Metal Table Base Wood Table Legs